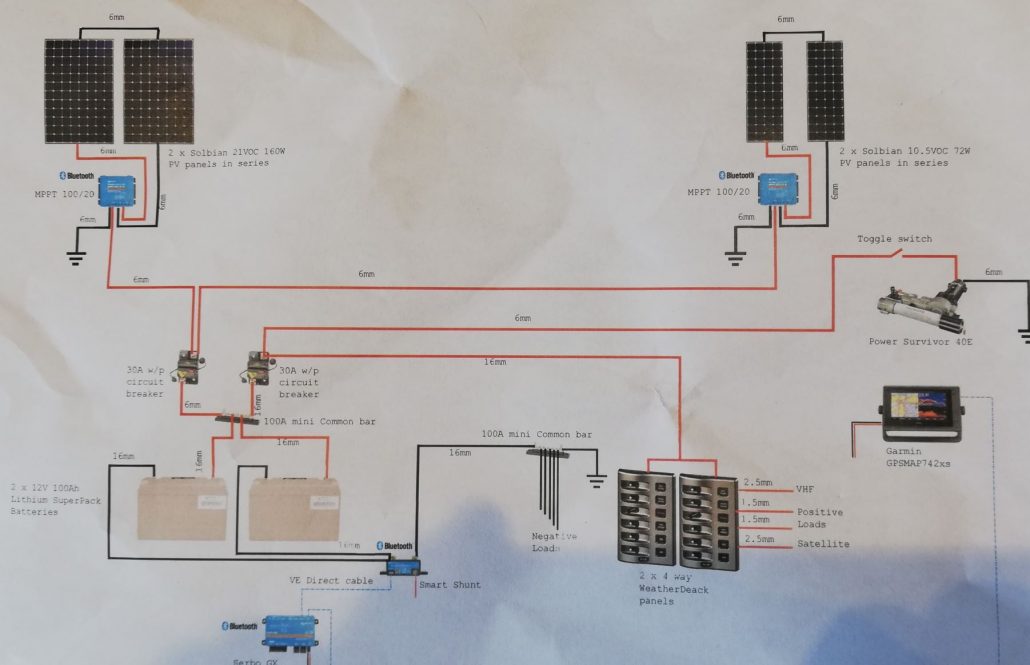

Power systems – batteries etc

You will pick up a recurring theme – that every piece of equipment I take must be super reliable and every system must have redundancy built in.

All my electronic equipment: Plotter, VHF radio, AIS, Autohelm, lighting and most importantly the watermaker all depend on a reliable power source. With this in mind it was an easy choice to go with Victron Energy as my power solution.

The solar panels are connected to a solar controller before they are able to charge the batteries. The front and aft panels each have their own charge controllers.

- Solar controller/charger:

Victron SmartSolar MPPT 100/20 0.7kg

The controller constantly monitors the voltage and current output of the solar panels. The Maximum Power Point Tracking(MPPT) technology intelligently maximises the energy-harvest to achieve a full charge in the shortest possible time. The advantage of a MPPT controller is most noticeable when the sky is partially clouded and light intensity is constantly changing which are the conditions for much of my route. The SmartSolar charge controller will even operate with a battery voltage as low as 0 Volts, provided the cells are not damaged.

Another bonus is the built-in Bluetooth. I can pair it with my smartphone for real time data. I have also connected them to a Victron GX module. See more info on the GX below.

The solar charge controllers are then connected to the batteries via a waterproof 30amp circuit breaker.

- Batteries:

Victron Lithium SuperPack 12,8V 100Ah 1280Wh 15kg

The batteries are simple plug and play and I have two connected in parallel. They have an internal switch that will disconnect the battery in case of over discharge, over charge or high temperature. I have sealed the housing to improve the IP43 (waterproof) rating.

The most important features of the lithium versus lead-acid batteries are:

- Weight saving of more than 50%

- They can be discharged below 85% without any issues

- The charge rate is much faster

- They do not need to be fully charged. In fact service life even slightly improves in case of partial charge instead of a full charge.

The batteries are then connected to a battery monitor and then a waterproof 30amp circuit breaker before connecting to the switch board where the power is distributed to the various circuits.

- Battery Monitor:

Victron Smartshunt 500A/50mV

The SmartShunt is an all in one battery monitor, only without a display. My smartphone acts as the display when needed via the built-in Bluetooth which allows me to read out all monitored battery parameters, like state of charge, time to go, historical information and much more. The SmartShunt is a good alternative for a battery monitor with a display, especially for systems where battery monitoring is needed but less wiring and clutter is wanted. The Smart Shunt is also connected to the Victron GX module.

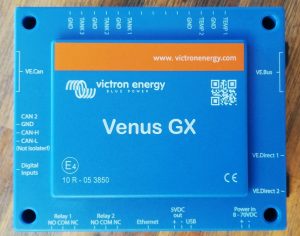

- The Venus GX:

This is the communication center of my installation. It allows me to talk to all Victron components in the system and ensure they are working in harmony. Monitoring of live data, and changing settings can be performed using my smartphone and my shore team will be able to monitor and adjust values remotely from any place in the world via the Victron Remote Management Portal.

How cool!

Huge thanks to Bruce Robinson from Powersol for his advice, ongoing support, assistance and sponsorship along with the support from Andre Du Rand of Victron Energy.